PROBLEM: A 10-km, three phase transmission line delivers power to a load rated 2000kW, 6.9kV and at 80% lagging power factor. The resistance and reactance of each line are 0.2 and 1.2 ohms per kilometer, respectively. What percentage of the power generated is lost in the transmission line?

SOLUTION:

SOLUTION:

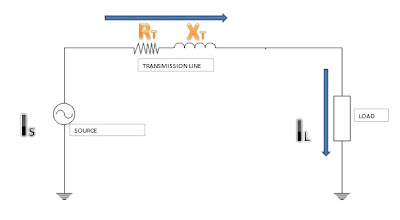

Similar to the previous problem, we should first draw the figure for us to understand clearly what is required for us to solve.

In this problem, we are asked to calculate the percentage of the power generated that was lost in the transmission line. Using the following given data below, we need to compute for the power that was lost in the line.

- 10 km distance of the transmission line.

- 2000kW load

- 6.9kV voltage at 80% lagging power factor

- line impedance of 0.2 +j1.2 ohms per km

Based upon the figure above, in order for us to compute for the line loss we should first solve for the line current.

LINE CURRENT = (kW) / (sqrt(3)*line voltage*power factor)

= (2,000,000) / (sqrt(3)*(6,900)*(0.8)

LINE CURRENT = 209.185 A

TOTAL IMPEDANCE = (0.2 + j1.2)ohms per km x 10km

= 2 + j12 ohms

TOTAL RESISTANCE = 2 ohms

We then solve for the total lost power in the transmission line using the 3(IsquaredR) formula.

POWER LOSS = 3*I*I*R

=3(209.185)(209.185)(2)

POWER LOSS = 262.55 kW

Therefore,

POWER GENERATED = POWER LOAD + POWER LOSS

= 2,000 +262.55

POWER GENERATED = 2262.55 kW

% Power Loss = Power Loss / Power Generated

= 262.55 / 2262.55

% Power Loss = 11.6%

Reference: 1001 Solved Problems in Electrical Engineering by Romeo Rojas Jr.

Comments

Post a Comment