PROBLEM: A 3-kilometer, 336ACSR, 3-wire short transmission line has an impedance of 2 + j5 ohms per wire. At the receiving end, a balanced 3-phase load and capacitor bank draws 3000kVA, 0.71 power factor lagging and 600kVAR respectively at 8000 volts per phase to neutral. Determine the power loss of the transmission line.

SOLUTION:

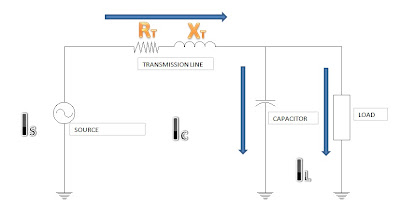

The first thing that we should do in analyzing any problem is to illustrate our interpretation of the problem into a figure which will make us better understand what is needed.

In this problem, we are asked to compute for the transmission line loss with the following given data:

- Transmission line impedance of 2 + j5

- 3-phase load of 3000kVA at 71% power factor lagging.

- Capacitor of 600kVAR

- 8000 volts per phase to neutral.

To see various conductor resistance for ACSR wires, you can refer to RESISTANCE TABLE

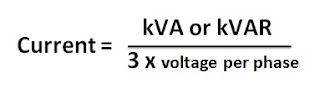

Basing upon the above diagram, we now compute for the current that passes through the capacitor and the load using the formula below.

IL = KVAL / (3 x Voltage L) = 3,000,000 /(3x8000) = 125A

θL = arccos(0.71) = 44.765 degrees

IC = kVARC /(3 xVoltage C) = 600,000 / (3x8000) = 25A

The next step is to calculate for the current that passes through the transmission line by adding the load current and the capacitor current vectorially.

IT = IC + IL

= 25 angle 90 degrees + 125 angle (-44.765 degrees)

= j25 +88.75 - j88.025

The final part of this solution is to compute for the total line losses in the three lines by using the power loss formula.

As a result, the total transmission line loss would be.

PLoss = 3 (108.85)2(2)PLoss = 71.09 kilowatts

Reference: 1001 Solved Problems in Electrical Engineering by Romeo Rojas Jr.

Comments

Post a Comment